| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | AllWin |

| Model Number : | SP250 |

| Certification : | ISO9001 |

| Price : | USD5000--USD70000/set |

| Payment Terms : | T/T, Western Union, MoneyGram |

| Supply Ability : | 30sets /month |

| Delivery Time : | 20-30 Working Days |

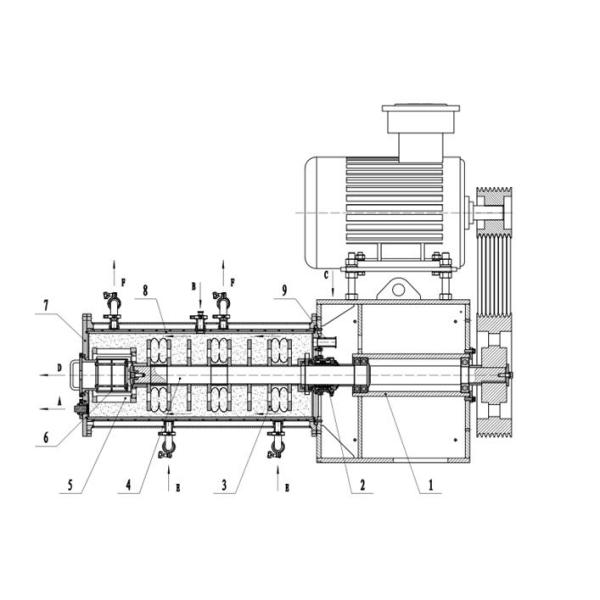

Wearable Titanium Dioxide Grinding Horizontal Bead Mill SUS304 Disc Grinding Machine

The Advantages:

L Great flow rate and super fine discharging

High production capacity and high efficiency

Wear-resistant grinding chamber

Double mechanical sealing with research and development indepent technology

High cooling efficiency with multiple cooling

Long time life and low maintenance.

With ISO9001 certification and more than 11 patents of sand mill

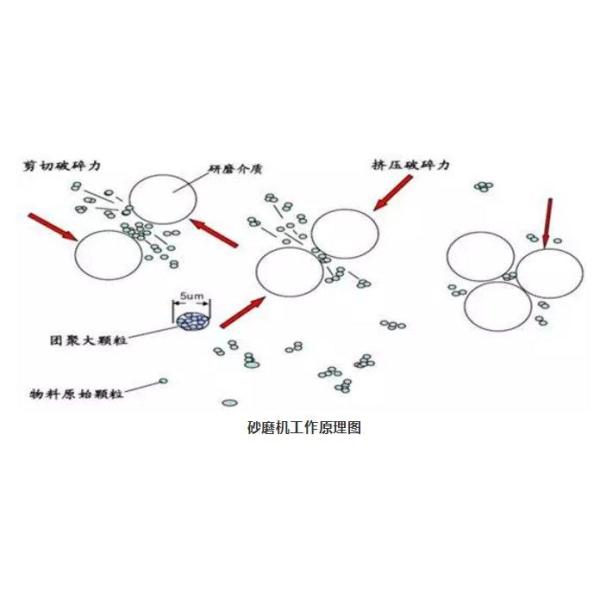

The working principle:

The working principle is to use the material pump to feed the solid-liquid mixture material that has been pre-dispersed and wetted by the mixer into the chamber, and the material and the grinding medium in the chamber are stirred by the high-speed rotating disperser, so that the solid particles in the material and the grinding media produce stronger collision, friction, and shearing effects with each other to achieve the purpose of accelerating the grinding of fine particles and dispersing .After grinding and dispersing, the material passes through a dynamic separator to separate the grinding medium and flows out of the discharge pipe.

The main techinical data:

The main Configuration instructions:

| No | Main parts materials | SP 250 Non Explosion-proof | Notes |

| 1 | External cylinder | 304 stainless steel | |

| 2 | Internal cylinder | PU coated 304 stainless steel | |

| 3 | Dispersing shaft | 40Cr with hard chromium plating | |

| 4 | Dispersing disk | PU coated 304 stainless steel | |

| 5 | Feeding and discharging end covers on the cylinder | 304 stainless steel | |

| 6 | Turbine centrifugal separator and pins | 304 stainless steel and YG6 pins | |

| 7 | Static discharge screen ring | Wire Wound screen ring with 304.Gaps: 0.5mm. | |

| 8 | Mechanical seal | Intelligent double mechanical seal with mandatory lubricating-cooling system | |

| 9 | Feeding pump | 1.5” ARO diaphragm pump; | |

10 | Appliance configuration | Non Explosion-proof machine, suitable for water base materials, motor 55kW. Non Explosion-proof parts: operation column,electrical appliance boxes;electric contact pressure gauge, temperature,solenoid valves with NO ex electrical contacts., Control system (button type) | |

| 11 | Fasteners and connecting parts | Stainless steel clamp-type connecting parts | Quick and convenient |

The production show:

The mature production and model of SP250, and have plentiful experiences in Chemical Fibre Titanium Dioxide.

The detailed parts:

Allwin research and development the double mechanical seal indepently.

The Packing and delivery: Wooden boxes and FUL or LCL container

The related products:(Dispersing machine and Movable Tank)

The efficiency of griding will be improved after enough pre-dispersing, So the dispersing machine also is very important.

|